Watch out! The optimization could be an obsession, everything written down below is out of our responsibility. If after this reading you think about optimizing 99,314% of your daily life it is not my fault.

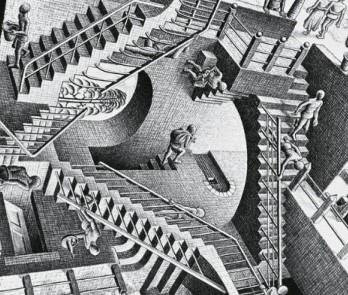

When it comes to optimization, and above all the path towards the Optimum, we must necessarily introduce another concept: complexity. Devil is in the details.

I lived close to this street, and there’s a thing you can notice crossing it, a (giant) step between it and the pavement.

Every day cross through it, from children to the elderly, on foot, by bike, by scooter, skate, wheelchair, roller-skating passing at different speed, running or walking the dog around. I saw trolleys breaking, children crashing down with their tricycles, runners stumbling, old people hesitating with their shopping bags, cyclists who risked breaking the rim of the bike several times (me).

How the design of this step affects all the world around it?

Think of a cyclist who breaks or bends the rim, the cost of changing it, maybe that of the mechanic or think, of the cost of replacing the wheels (maybe some of them cannot even be replaced), and so the cost of a new trolley. Then, think about those who produce these things (probably in China), then the money we pay to the producers, the transport (so also the problem of fuel for the transport, pollution, and the climate change??) …not to think about the runner who gets injured and loses the opportunity to train for a race, does not win it, goodbye career …

And those who are cycling to work? maybe they can arrive late and lose their jobs. And the elderly people who risk their lives? How many people? In one day and then in a week then in a month and then in a year and in years …

But ehi, pay attention!

Analyzing the reason for the step only from the point of view of these issues is not correct. For example, the profile of the road is made so that on rainy days the water flows naturally to the side of the carriageway. So if there were no steps, as soon as the rain starts to fall the sidewalk floods and the water would no longer flow to the side.

So where is the design optimization in this case?

The Optimum would be to find a form or a solution that can solve both problems in the best possible way, or, more likely today, to balance design decisions against a priority of problems to be solved or advantages that we prefer to have. Think about how many variables it is possible to work on, here is where today you can find AI techniques or machine learning or deep learning etc. where these tools are simply used to solve many small and simple problems against of an immense or unthinkable number of data to be faced by a person or a team. The world is full of steps, and the search for optimization lies in understanding how the modification of one part affects the others.

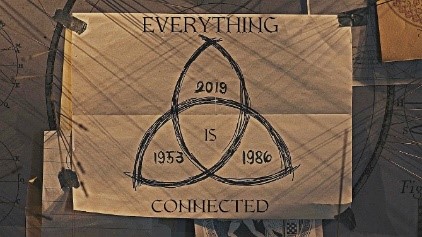

Everything is connected.

Ok, I have probably exaggerated a bit… but that actually is the reality. The optimization of a part does not always have an impact on the assembly or better, usually the more complex is the assembly, the less effective is the optimization of a single component.

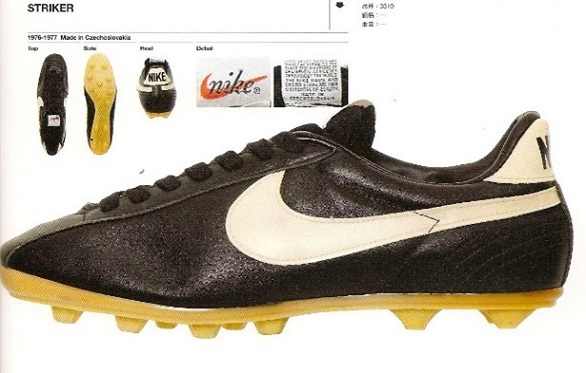

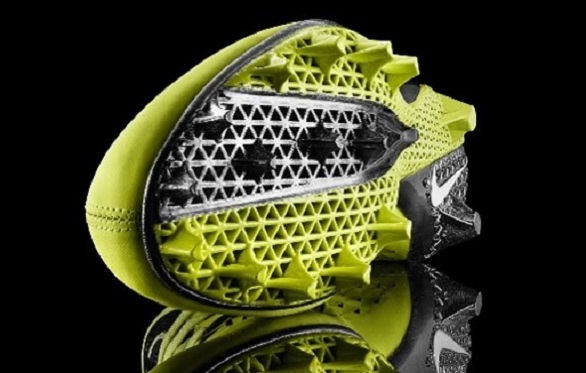

For example, if we want to increase the performance of a football shoe starting from the sole, we can try to optimize the shape of a single cleat, what influence would it have? Instead, think about modifying not just one but all the cleats. Now, imagine optimizing the positioning of these, it would be a completely different result. Finally, think of optimizing the position of the cleats and optimizing the shape of every single one, not only for the position where it is located but for the combined effect with the others on the overall performance. This comes much closer to the concept of optimization.

Here it is easier to understand how, inside a system, the various parts influence the final result. In engineering when we want to optimize something, we approach the problem to work on the largest amount of variables interested in (or the min number of variable linked to the problem, or the most important variables for the problem, to achieve the result faster or easier or with less computational cost or… uknowhatimsayin¿

In general, there are many engineering approaches to optimize the geometry of thing. Are you connecting everything? Are you thinking about topology optimization? And its meaning, right? DON’T!

(be careful on top opt video )

The topology optimization techniques in engineering it is not actually a “topology optimization” in the broadest sense. Let me explain better it. The classical TO is a kind of optimization of the material distribution of your component, so that is the design space. Generally speaking, this tech is an algorithm that understands the stress distribution under a precise load case and leaves the material just where it is more crucial for mechanical behaviour.

If you think about nature where optimization is the principal business and aim, you will understand how this approach is dumb and just a step of lots more to be done. So if sometimes you perform a TO and you see a side or an edge unaltered, it is because you are optimizing the distribution inside your (not optimized) component and the final result will not be a geometry (topology) optimization of material in its broadest sense. It is the same as a tree growing next to the sideway where the branches are stopped to grow by the boundaries, so the limited design space.

When you see complex designs, think about it, they have the right to exist ONLY if they optimize something in the result. Complexity is the result of nature just because the way it has been designed is a simple and logic methodology. The complexity with no clue is not engineering.

Finally, imagine to optimize not a component or assembly rather a dynamics or a business mechanism. If you can imagine the problems, the opportunities, the variables and their intertwining, their importance in the final result, you can understand how important the AM world is for today’s manufacturing and how many aspects have not yet been implemented and how much potential is still unexplored. And of course, the difficulty approaching it for production, for example.

At .Zero we complicate things just if they have to, and we do things in AM only if there is a good reason to.

See you at the next episode to further intertwine these connections and to understand what the next giant steps will be for .ZERO and for DfAM.

By the way see this if you love music composition and maths https://www.youtube.com/watch?v=62tIvfP9A2w&feature=emb_title

FL