Imagine a new way of bringing your ideas to life: Design for Additive Manufacturing

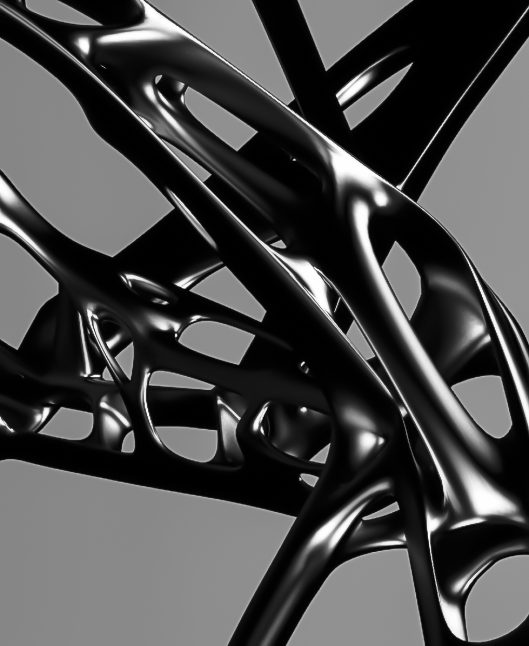

Explore the unlimited potential of Design for Additive Manufacturing (DfAM) to industrialize products impossible to make with traditional technologies. With DfAM, you can take your product design to new horizons and unleash your creativity like never before.

Imagine a new way of bringing your ideas to life: Design for Additive Manufacturing

Explore the unlimited potential of Design for Additive Manufacturing (DfAM) to industrialize products impossible to make with traditional technologies. With DfAM, you can take your product design to new horizons and unleash your creativity like never before.

What is design for additive manufacturing?

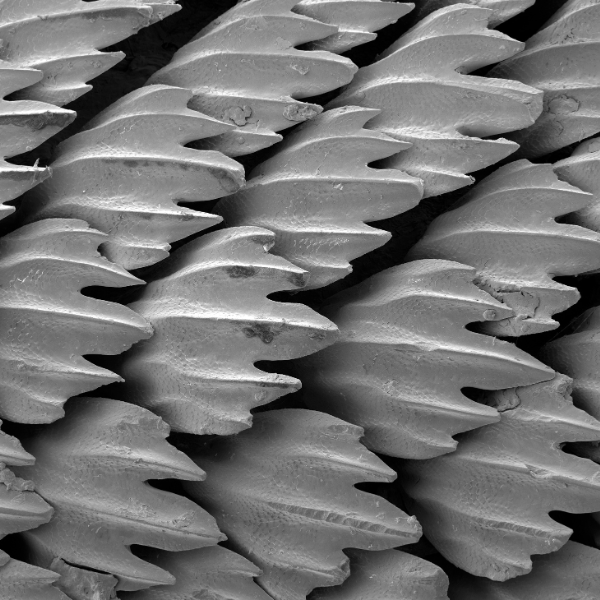

Design for Additive Manufacturing is the future of industrial design, it is a highly innovative product engineering service, which by exploiting advanced skills and technologies, allows the development of innovative products both from the point of view of design and their function.

One of the main features of this approach is the possibility of prototyping and producing with the same 3D printing technology, making the production workflow more flexible and rapid.

By integrating DfAM principles into your design process, you will teleport your manufacturing into the future, as our leading customers in the fashion, automotive, medical and sports protection industries have already done.

DfAM - A service for designing with precision and efficiency

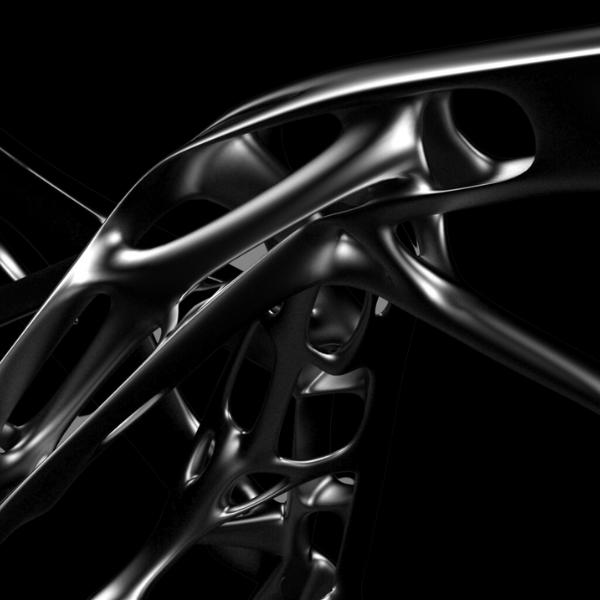

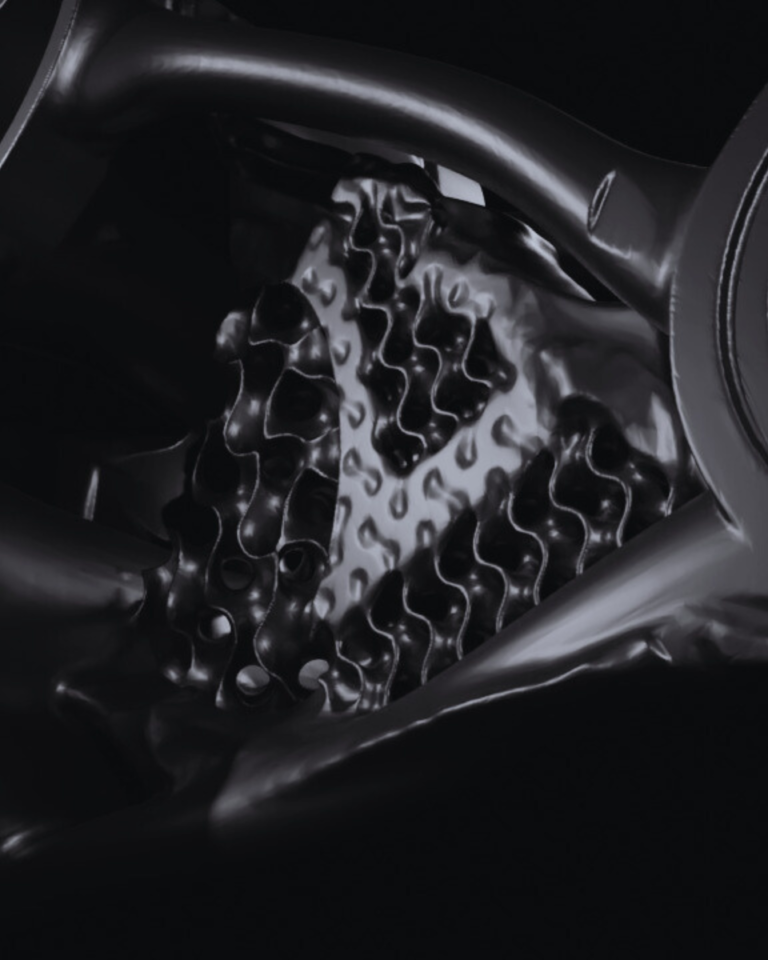

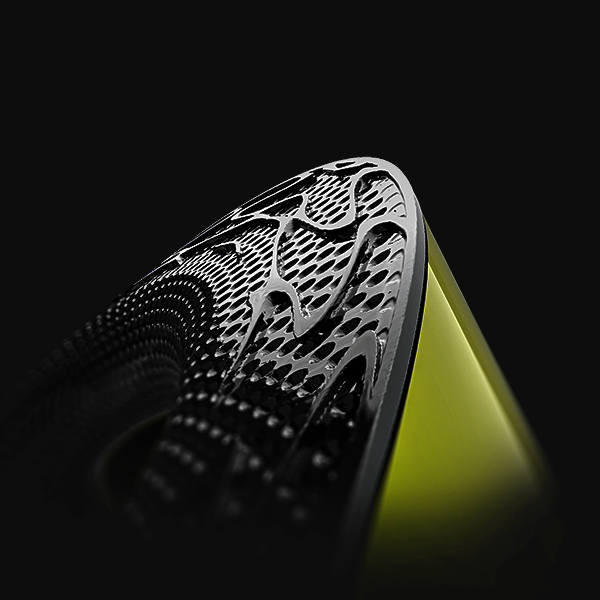

Design for Additive Manufacturing allows you to create highly customized and complex components and finished products with previously impossible precision and efficiency. By exploiting the Additive Manufacturing capabilities , it is also possible to reduce material waste, minimize production times and obtain faster production cycles.

Trying Design for Additive Manufacturing means breaking the limits of the impossible.Provare il Design for Additive Manufacturing vuol dire infrangere i limiti dell’impossibile.

Examples of developed products

Thanks to our Design for Additive Manufacturing skills we have managed to create innovative products, such as:

- Helmets with innovative 3D printed safety systems

- Exclusive design footwear

- Interior furnishings with innovative shapes and geometries

- Ski goggles with a revolutionary design and more performance

- Sports radiators with greater heat exchange efficiency and a considerable weight reduction

- Highly customizable orthopedic prostheses with very quick production times

- More comfortable bike saddles

We are a team of innovation pioneers

Our reality is made up of an engineering team, with people who have developed cutting-edge skills in Design for Additive Manufacturing at the centers of excellence of the Polytechnic of Milan and Turin.

Innovation, engineering, nature-inspired design, sustainability and quality are the pillars of our vision. We collaborate with leading brands in the fashion, automotive and sports equipment sectors, with whom we have signed rigorous confidentiality agreements.

L’innovazione, l’ingegnerizzazione, il design ispirato alla natura, la sostenibilità e la qualità sono i pilastri della nostra visione.

Collaboriamo con brand leader nei settori della moda, dell’automotive e delle attrezzature sportive, con cui abbiamo siglato rigorosi accordi di riservatezza.

We operate all over the world

Our field of action is the entire world. With the digital process of Design for Additive Manufacturing, we can cross any geographical border. After completing the engineering and prototyping of the product in house, we select the best partners globally to start the industrialization of the final product.

Guarantee on the result

we guarantee each Customer the achievement of the expected result, respecting the value of the quality of the service on which our foundations are built. This peculiarity of ours allows us to build long-lasting relationships of trust with our customers.

How our service works

-

Consultancy and feasibility analysis

Starting from your production needs, we set a production objective, after which we carry out a feasibility analysis of the product to be created, and then identify the best technologies and the appropriate materials to create it.

-

Concept

We develop the Alpha d model and we print the first provisional samples, in order to evaluate the related production process to carry out the first aesthetic and functional tests of the product itself.

-

Engineering

We engineer the 3D model of the product and progressively adjust the prototype by listening to customer feedback, getting closer to the most suitable solution. To satisfy the stylistic, economic and temporal needs required.

-

Prototyping

We start the modification and validation loop between the 3D model and the physical prototype of the product, to identify the appropriate finishing touches and print the final product.

-

Industrialization

We bring the customer to production to industrialize the product, selecting the right partner for his specific needs in terms of cost reduction, reduction of production times and geographical localization.

CONTACT US

Experience the benefits of DfAM on your own industrialization process

Book a free consultation directly with our experts and you will discover how to use DfAM to meet your specific needs. If at the end of the consultancy you are interested in unleashing the potential of DfAM, our engineering team will guide you from concept development to the industrialization process of your revolutionary product, with particular attention to guaranteeing the result.